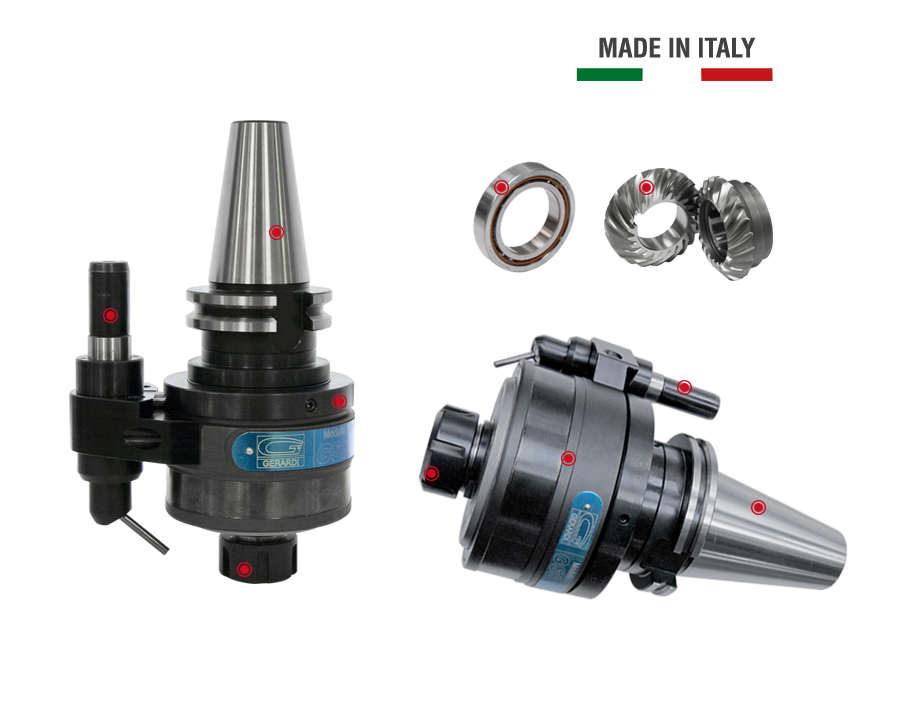

Spindle Speeders

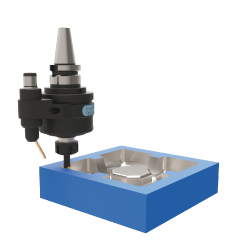

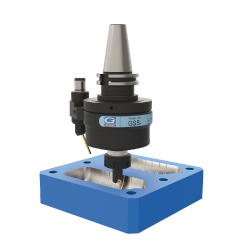

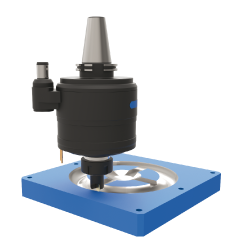

Spindle Speeders for milling, drilling and high speed machining

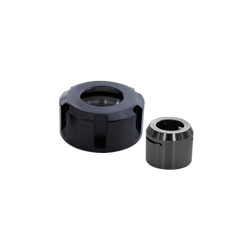

The spindle speeders have been designed and developed to offer a product that ensures maximum reliability and accuracy in milling and drilling. From design to static and dynamic testing of the finished product, our spindle speeders use the most advanced technical and technological know-how.

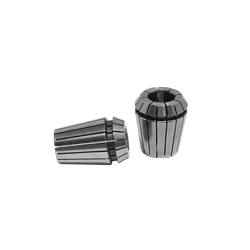

The compact construction, the heat-treated steel parts and the ground gears on the involute guarantee transmission of high power ratings with amazingly low noise levels. The spindle is supported by a set of preloaded precision ball bearings with oblique contact that ensure greater strength and rotation precision less than 0,01 mm.

The spindle speeders series can be mounted on traditional machines and on machines with automatic tool change. Our products have always stood out for their sturdiness, flexibility and easy use and maintenance and the spindle speeders series is an additional proof of such outstanding features.